Tube Laser Cutting Systems Hobbycraft

Metal fabricators are well-versed in the basics of fiber laser cutting technology for flat sheet processing. But what about tube cutting? It's quite a lot.

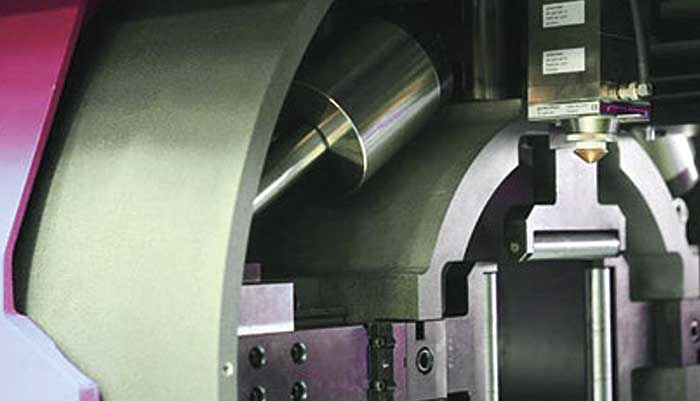

Lasertube systems, our 2D or 3D laser cutting system for tubes, bars, profiles and tubes from 12 mm up to 610mm (.5" to 24-") in diameter and 18 m (60") in length, are called Lasertube systems.